UV油漆生产线

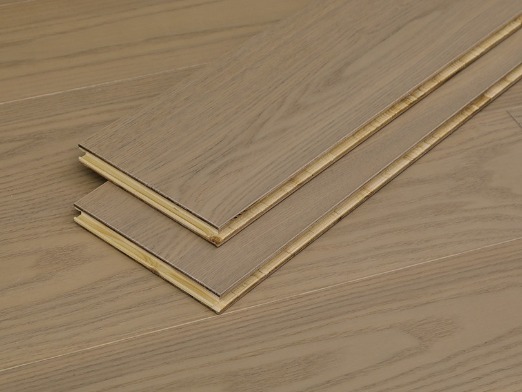

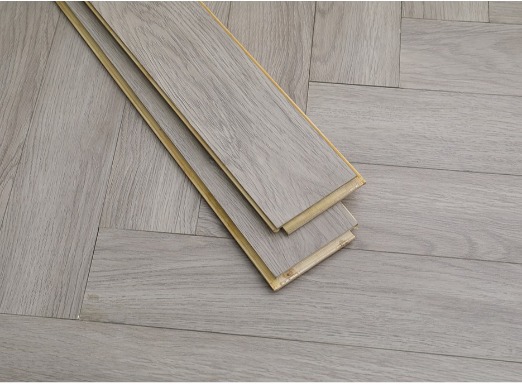

In our factory, exquisite natural wood veneers are combined with high-stability substrates to create high-end flooring products. The painting process is the core of this transformation. The paint finish is not only a protective layer, but also the soul of the product - it defines the aesthetic, tactile feel, and durability. Our advanced wood veneer paint finish production line combines precision engineering and craftsmanship, and is designed for superior quality.

Precision operation: our core production process flow

Our automated painting line is a carefully designed journey, ensuring that every piece of board material receives a flawless and natural wood veneer surface.

1. Pre-treatment and sanding: The journey begins with precise thickness determination and sanding. The high-precision wide-belt sander ensures that every veneered board achieves absolute flatness and smoothness. This crucial step lays the foundation for excellent adhesion and perfect performance of subsequent coatings.

2. Penetration and Primer Coating: The processed boards enter the automatic coating area. We primarily utilize an advanced UV roller coating system. The UV primer is evenly applied, effectively penetrating and sealing the wood conduits, forming a uniform and stable substrate. The boards are then immediately passed through the UV curing tunnel, where the paint is instantly cured under ultraviolet light, forming a hard, easily sandable primer layer.

3. Intermediate sanding: After the primer dries, the board undergoes a fine sanding process. This step removes any burrs that may have formed due to the wood absorbing the paint, leaving the surface as smooth as silk and preparing it for the topcoat application.

4. Topcoat Application and Curing: The final character of the product is born here. According to different aesthetic needs - from natural matte touch to deep mirror high gloss - we apply multiple layers of high-performance UV topcoat. Our production line supports flexible coating processes:

· Roll coating: used to obtain an extremely uniform and consistent paint film.

· Curtain coating: used to form an extremely flat, thick film finish, especially suitable for high-gloss effects.

Each layer of paint is instantly cured by UV light, creating a rich texture and a sturdy protective layer as it overlays the previous one, eliminating the need to wait for drying time.

5. Quality Inspection and Packaging: Each painted board undergoes rigorous inspection under standard lighting to ensure consistency in gloss, color, and texture. Only products that meet our stringent standards are carefully packaged and ready for delivery.

Our technological advantage: Quality stems from craftsmanship

· Commitment to environmentally friendly production: We adhere to the use of low VOC, environmentally friendly UV coatings and practice sustainable development. The efficient curing process minimizes energy consumption and eliminates solvent emissions.

· Excellent consistency and efficiency: Automated precision painting ensures flawless and consistent paint film thickness and uniformity on every square inch. Instant curing technology achieves high production efficiency, ensuring reliable delivery for large-scale orders.

· Rich design expressiveness: Our production line can achieve diverse surface effects:

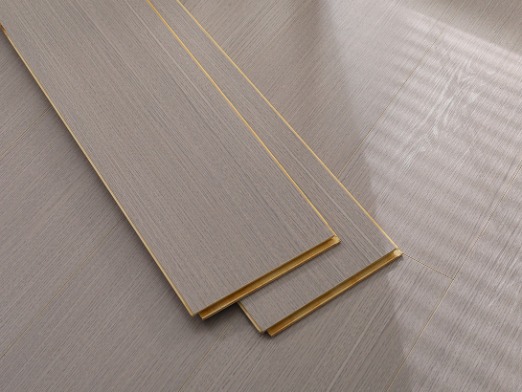

· Glossiness: ranging from soft matte (5-10°), silky soft gloss (20-40°), to semi-gloss (50-70°), and even mirror-like high gloss (above 85°).

· Surface texture: Extremely smooth, delicate velvet, or hand-scraped antique effect.

· Color and effect: Transparent coating that highlights natural wood grain, full-bodied solid color paint, as well as popular fashionable tones such as white wash and smoky finish.

Commitment to our partners

This advanced production line is not just a machine; it represents our commitment to you. It signifies our guarantee to provide you with stable production capacity, excellent quality, and creative flexibility. Whether you need the warm matte finish of classic oak or the textured gray of modern ash wood, our painting capabilities can confidently turn your design ideas into marketable products.

We sincerely invite you to collaborate with a factory that regards "coating" as its core process.

简体中文

简体中文 English

English